Hand-cut doughnut shaping offers artisanal precision and unique texture variations that enhance the eating experience, while extruded doughnuts provide uniformity and higher production efficiency. Hand-cut doughnuts typically showcase irregular edges and a more rustic appearance, appealing to consumers seeking a homemade feel. Extruded shaping allows for consistent size and shape, making it ideal for large-scale bakeries focused on speed and volume.

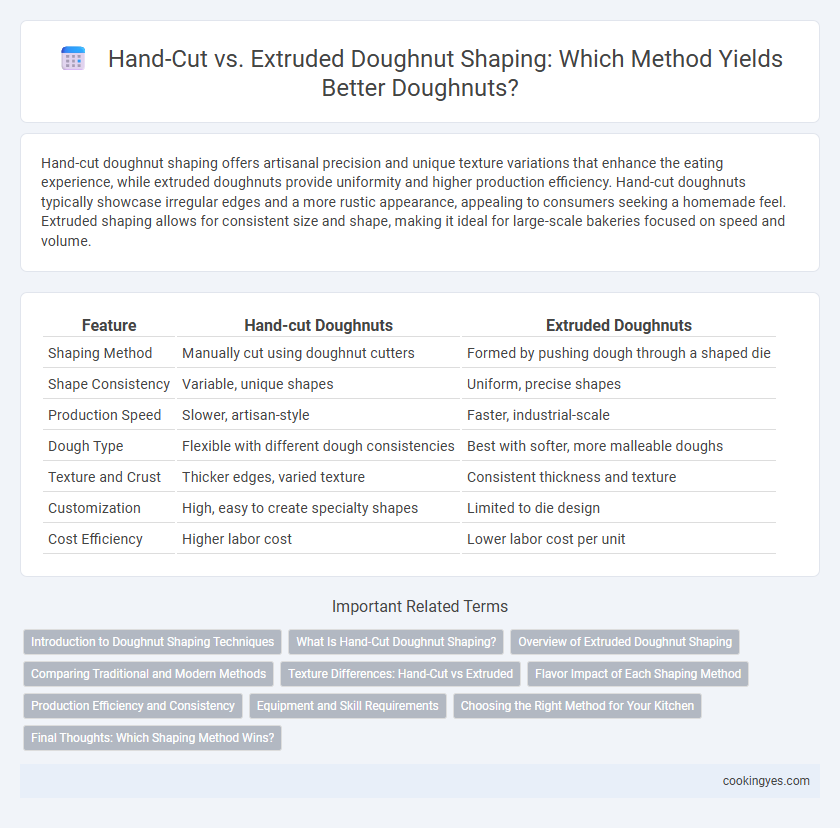

Table of Comparison

| Feature | Hand-cut Doughnuts | Extruded Doughnuts |

|---|---|---|

| Shaping Method | Manually cut using doughnut cutters | Formed by pushing dough through a shaped die |

| Shape Consistency | Variable, unique shapes | Uniform, precise shapes |

| Production Speed | Slower, artisan-style | Faster, industrial-scale |

| Dough Type | Flexible with different dough consistencies | Best with softer, more malleable doughs |

| Texture and Crust | Thicker edges, varied texture | Consistent thickness and texture |

| Customization | High, easy to create specialty shapes | Limited to die design |

| Cost Efficiency | Higher labor cost | Lower labor cost per unit |

Introduction to Doughnut Shaping Techniques

Hand-cut doughnuts offer a rustic texture and varied shapes by using cutters to slice dough before frying, preserving a traditional appearance. Extruded doughnuts achieve uniformity and efficiency through machines that push dough into continuous rings, ideal for large-scale production. These shaping techniques influence dough consistency, cooking time, and final product aesthetics, essential for bakeries optimizing production and quality.

What Is Hand-Cut Doughnut Shaping?

Hand-cut doughnut shaping involves manually cutting dough into circular shapes using cutters or by hand, ensuring each doughnut has a unique, artisanal appearance. This method allows for varied thickness and texture, contributing to a traditional, homemade quality often preferred by small bakeries. Hand-cut doughnuts typically exhibit irregular edges and a fluffier interior, distinguishing them from uniform, machine-extruded counterparts.

Overview of Extruded Doughnut Shaping

Extruded doughnut shaping involves forcing dough through a specialized machine that cuts and shapes the dough into consistent rings, ensuring uniform size and texture. This method increases production speed and efficiency compared to hand-cutting, making it ideal for large-scale doughnut manufacturing. Extruded doughnuts typically have a smoother surface and denser crumb, which affects frying and glazing characteristics.

Comparing Traditional and Modern Methods

Hand-cut doughnuts, crafted using traditional methods, offer a distinct texture and irregular, rustic shape that appeals to artisanal preferences, retaining the dough's natural airiness. Extruded doughnuts, produced through modern machinery, ensure uniformity, faster production rates, and consistent size, which is ideal for large-scale commercial bakeries. The choice between hand-cut and extruded methods impacts not only visual appeal but also texture and production efficiency in doughnut shaping.

Texture Differences: Hand-Cut vs Extruded

Hand-cut doughnuts exhibit a denser, chewier texture due to uneven thickness and slower frying, creating varied crust development. Extruded doughnuts feature a consistent, lighter crumb with a uniform, airy interior resulting from controlled dough flow and rapid frying. Texture differences directly impact mouthfeel, with hand-cut doughnuts offering rustic bite and extruded versions delivering smooth, tender consistency.

Flavor Impact of Each Shaping Method

Hand-cut doughnuts often retain a denser texture and more uneven surface, which enhances flavor absorption from glazes and toppings. Extruded doughnuts feature a uniform shape and consistent crumb structure, promoting even cooking and a lighter, airier bite that highlights subtle dough flavors. The shaping method influences the flavor profile by affecting how the dough interacts with heat and toppings during frying.

Production Efficiency and Consistency

Hand-cut doughnuts offer artisanal appeal with varied shapes but lower production efficiency and inconsistent sizing due to manual processes. Extruded doughnuts utilize automated machinery, enabling high-speed production with uniform shapes and consistent quality for large-scale operations. Choosing extruded shaping enhances operational efficiency and product standardization critical for commercial doughnut production.

Equipment and Skill Requirements

Hand-cut doughnuts require minimal equipment, typically just a doughnut cutter and a flat surface, allowing for artisanal shapes and slight variations in size. Extruded doughnuts rely on specialized machinery that forces dough through shaped nozzles, producing uniform rings quickly but demanding technical skill to operate and maintain the equipment. Skilled operators are essential for extruded doughnuts to ensure consistent product quality and efficient machine performance.

Choosing the Right Method for Your Kitchen

Hand-cut doughnuts offer artisanal texture and unique irregularities that appeal to small bakeries focusing on craft quality, while extruded doughnuts provide uniformity and higher production efficiency suited for commercial kitchens. Selecting hand-cut methods enhances customization and presentation, ideal for limited batch sizes, whereas extruded doughnuts optimize consistency and speed, essential for high-volume operations. Evaluate kitchen scale, desired doughnut appearance, and throughput demands to determine the most effective shaping technique.

Final Thoughts: Which Shaping Method Wins?

Hand-cut doughnuts offer a classic, artisanal texture with slightly uneven edges that enhance frying consistency and flavor absorption, appealing to traditionalists. Extruded doughnuts provide uniformity in shape and size, optimizing baking times and presentation for commercial production. The final choice depends on whether prioritizing artisanal quality or production efficiency is more important for the desired doughnut experience.

Hand-cut vs Extruded for Doughnut Shaping Infographic

cookingyes.com

cookingyes.com