Air chilling preserves the natural flavor and texture of chicken by cooling carcasses with cold air, reducing water absorption and resulting in a firmer product. Water chilling involves immersing chicken in cold water, which can increase weight due to water retention but offers rapid temperature reduction and cost efficiency. Both methods impact microbial control and shelf life differently, influencing processing choices based on quality priorities and operational costs.

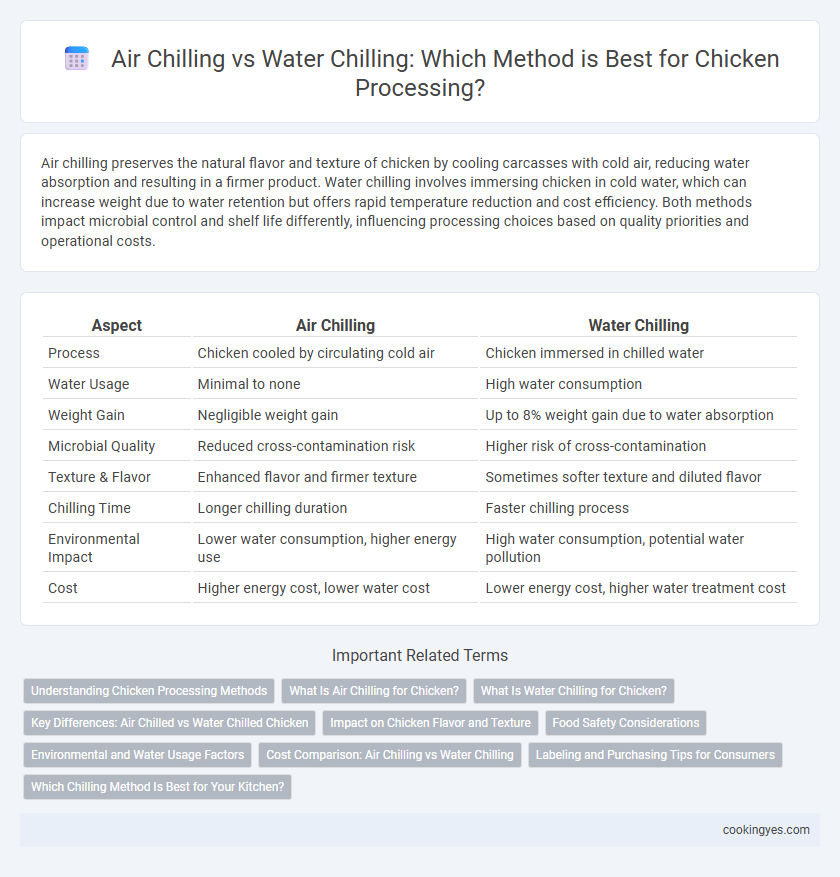

Table of Comparison

| Aspect | Air Chilling | Water Chilling |

|---|---|---|

| Process | Chicken cooled by circulating cold air | Chicken immersed in chilled water |

| Water Usage | Minimal to none | High water consumption |

| Weight Gain | Negligible weight gain | Up to 8% weight gain due to water absorption |

| Microbial Quality | Reduced cross-contamination risk | Higher risk of cross-contamination |

| Texture & Flavor | Enhanced flavor and firmer texture | Sometimes softer texture and diluted flavor |

| Chilling Time | Longer chilling duration | Faster chilling process |

| Environmental Impact | Lower water consumption, higher energy use | High water consumption, potential water pollution |

| Cost | Higher energy cost, lower water cost | Lower energy cost, higher water treatment cost |

Understanding Chicken Processing Methods

Air chilling preserves chicken flavor and texture by rapidly cooling carcasses with cold air, reducing bacterial contamination without water absorption. Water chilling involves submerging chickens in cold water, promoting faster cooling but increasing water retention and potential cross-contamination risks. Understanding these methods is crucial for food safety, quality control, and consumer preference in poultry processing.

What Is Air Chilling for Chicken?

Air chilling for chicken involves hanging whole birds in cold, purified air chambers where temperatures range between 0degC to 4degC, allowing the carcasses to cool without direct contact with water. This method reduces water absorption, enhancing the flavor and texture while lowering bacterial contamination compared to traditional water chilling. Air chilling is widely adopted in premium poultry processing for producing firmer, less watery chicken with a longer shelf life and minimal cross-contamination risks.

What Is Water Chilling for Chicken?

Water chilling for chicken is a processing method where carcasses are submerged in cold water or a chilled water bath to rapidly lower their temperature after slaughter. This technique helps inhibit bacterial growth, preserve meat quality, and extend shelf life by maintaining optimal cold conditions. Compared to air chilling, water chilling can lead to higher water retention in the chicken, affecting texture and flavor profiles.

Key Differences: Air Chilled vs Water Chilled Chicken

Air chilling cools chicken by circulating cold air around the carcasses, resulting in less water retention and a firmer texture, while water chilling immerses the chicken in cold water, increasing moisture content and weight. Air chilled chicken typically maintains a more natural flavor and lower bacterial contamination risk, whereas water chilled methods may introduce cross-contamination if water quality is not properly managed. The choice between air and water chilling impacts product quality, shelf life, and processing efficiency in poultry production.

Impact on Chicken Flavor and Texture

Air chilling preserves the natural flavor of chicken by avoiding water absorption, resulting in a firmer texture and enhanced juiciness during cooking. Water chilling can lead to slightly diluted flavor and a softer texture due to water absorption during the process. Choosing air chilling supports a more robust taste profile and better mouthfeel preferred by chefs and consumers seeking high-quality poultry.

Food Safety Considerations

Air chilling in chicken processing reduces cross-contamination risk by avoiding water reservoirs that can harbor pathogens, enhancing food safety. Water chilling involves immersing carcasses in chilled water baths, which may spread bacteria like Salmonella and Campylobacter if not properly managed. Maintaining strict hygiene protocols and monitoring microbial loads are critical in both methods to ensure safe poultry products.

Environmental and Water Usage Factors

Air chilling chicken significantly reduces water consumption compared to traditional water chilling methods, lowering environmental impact by minimizing wastewater production and energy use associated with water treatment. Water chilling requires large volumes of clean water and generates substantial wastewater that demands extensive treatment to prevent pollution. Selecting air chilling supports sustainable poultry processing by conserving water resources and reducing the carbon footprint linked to water handling and disposal.

Cost Comparison: Air Chilling vs Water Chilling

Air chilling of chicken typically incurs higher initial equipment costs but reduces water usage and wastewater treatment expenses, resulting in potential long-term savings. Water chilling systems usually have lower upfront costs but involve significant ongoing water consumption and higher energy costs for pumping and cooling. Evaluating the total cost of ownership, including utilities and environmental compliance, is crucial for choosing between air chilling and water chilling in poultry processing.

Labeling and Purchasing Tips for Consumers

Air chilled chicken is labeled as processed without water immersion, preserving natural flavor and texture, while water chilled chicken indicates immersion in cold water baths for rapid cooling. Consumers should look for labels specifying "air chilled" to avoid added water weight and potential contaminants, ensuring a fresher product. When purchasing, prioritize air chilled chicken for enhanced taste and reduced environmental impact, especially in markets highlighting clear processing methods.

Which Chilling Method Is Best for Your Kitchen?

Air chilling preserves chicken flavor and texture by rapidly cooling carcasses with cold air, reducing water absorption and waste. Water chilling, using cold water baths, is faster and cost-effective but increases moisture content and potential cross-contamination risks. Choosing the best chilling method depends on kitchen priorities such as product quality, processing speed, and hygiene standards.

Air Chilling vs Water Chilling for Chicken Processing Infographic

cookingyes.com

cookingyes.com