Calcium chloride enhances milk setting by restoring calcium balance, improving coagulation, and creating a firmer curd during cheese making. Milk without additives may struggle to set properly, especially if pasteurized or stored, resulting in softer curds and lower yields. Using calcium chloride optimizes cheese texture, yield, and overall quality by facilitating stronger curd formation.

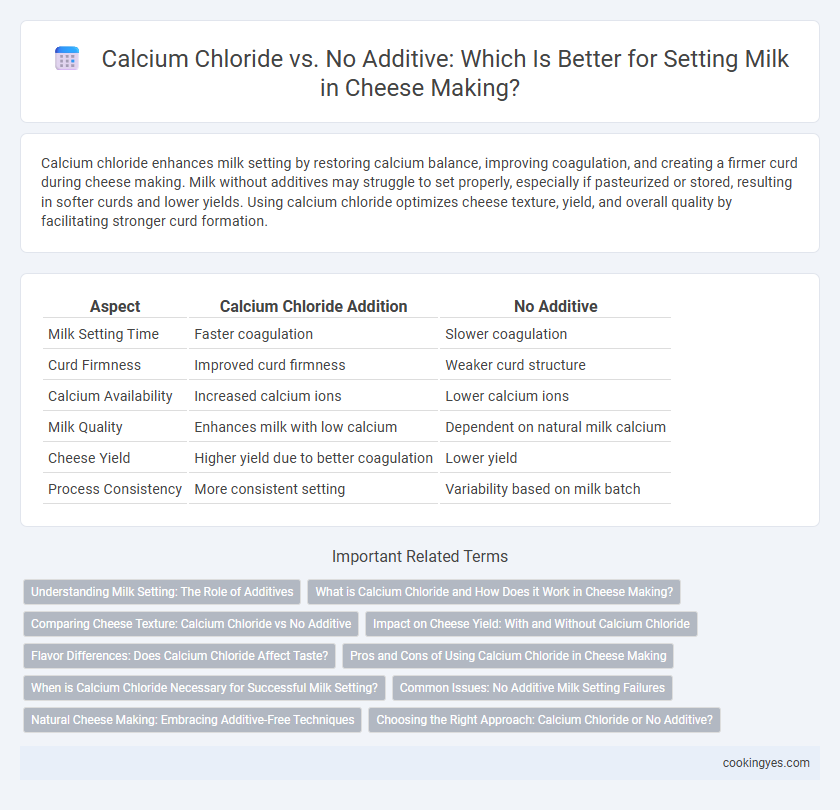

Table of Comparison

| Aspect | Calcium Chloride Addition | No Additive |

|---|---|---|

| Milk Setting Time | Faster coagulation | Slower coagulation |

| Curd Firmness | Improved curd firmness | Weaker curd structure |

| Calcium Availability | Increased calcium ions | Lower calcium ions |

| Milk Quality | Enhances milk with low calcium | Dependent on natural milk calcium |

| Cheese Yield | Higher yield due to better coagulation | Lower yield |

| Process Consistency | More consistent setting | Variability based on milk batch |

Understanding Milk Setting: The Role of Additives

Calcium chloride enhances milk setting by restoring calcium balance, improving curd firmness and yield, especially in pasteurized or refrigerated milk where natural calcium is reduced. Milk without additives often results in weaker curds and slower coagulation, impacting overall cheese texture and production efficiency. Utilizing calcium chloride optimizes enzymatic activity during coagulation, ensuring consistent and higher quality cheese outcomes.

What is Calcium Chloride and How Does it Work in Cheese Making?

Calcium chloride is a vital additive in cheese making that restores the balance of calcium ions in pasteurized or homogenized milk, improving coagulation and curd firmness. It enhances the action of rennet by stabilizing casein proteins, resulting in a more consistent and efficient milk setting process. Without calcium chloride, milk may produce weak or insufficient curds, leading to lower cheese yield and inferior texture.

Comparing Cheese Texture: Calcium Chloride vs No Additive

Calcium chloride enhances milk clotting by restoring calcium levels, resulting in a firmer, more cohesive cheese curd compared to using no additive. Without calcium chloride, milk often produces a softer, grainier texture due to weaker curd formation and reduced firmness. This difference significantly impacts the final cheese quality, influencing moisture retention and texture consistency.

Impact on Cheese Yield: With and Without Calcium Chloride

Using calcium chloride in milk setting enhances calcium ion availability, improving coagulation strength and curd firmness, which directly increases cheese yield. Without calcium chloride, especially in pasteurized or aged milk, slower coagulation and weaker curds result in lower moisture retention and reduced final cheese output. Studies show that calcium chloride addition can boost cheese yield by up to 10%, optimizing production efficiency and product quality.

Flavor Differences: Does Calcium Chloride Affect Taste?

Calcium chloride stabilizes milk's pH and enhances curd firmness, subtly impacting the cheese's texture without imparting a strong flavor. Cheese made without additives may have a softer texture but can exhibit more pronounced natural milk flavors. Flavor differences between calcium chloride-treated and untreated milk are generally minimal, with texture and consistency being the primary distinctions.

Pros and Cons of Using Calcium Chloride in Cheese Making

Calcium chloride enhances milk coagulation by restoring calcium balance lost during pasteurization, resulting in firmer curds and higher cheese yield. Without additives, natural calcium levels may lead to slower coagulation and softer curds, but avoid any risk of over-firming or altered flavor profile. Using calcium chloride requires precise dosing to prevent overly brittle curds and maintain desired cheese texture and taste.

When is Calcium Chloride Necessary for Successful Milk Setting?

Calcium chloride is necessary for successful milk setting when using pasteurized, homogenized, or aged milk with reduced calcium content, as it restores calcium balance critical for proper coagulation. It improves curd firmness, reduces setting time, and enhances enzyme activity, key factors in cheese yield and texture. Milk fresh from raw sources typically does not require calcium chloride, as natural calcium levels suffice for efficient curd formation.

Common Issues: No Additive Milk Setting Failures

Milk setting failures often occur when no calcium chloride is added, as the milk's natural calcium levels may be insufficient to achieve proper curd formation. Lack of calcium chloride can lead to weak or incomplete coagulation, resulting in a fragile curd that is difficult to cut and handle during cheese production. Calcium chloride improves milk's calcium balance, enhancing rennet activity and producing a firmer, more consistent curd essential for high-quality cheese.

Natural Cheese Making: Embracing Additive-Free Techniques

Calcium chloride plays a crucial role in natural cheese making by restoring milk's calcium balance, improving curd firmness, and ensuring consistent coagulation, especially when using pasteurized or refrigerated milk. Opting for no additive techniques preserves the pure, unaltered profile of raw milk but often results in softer curds and longer setting times due to diminished enzymatic activity. Embracing additive-free methods aligns with traditional artisanal cheese practices, emphasizing natural microbial flora and minimal intervention for authentic flavor development.

Choosing the Right Approach: Calcium Chloride or No Additive?

Calcium chloride enhances milk setting by restoring calcium levels lost during pasteurization, improving curd firmness and yield in cheese making. Using no additive may suffice with fresh, high-quality milk but risks weaker curd and lower yields in pasteurized or low-calcium milk. Selecting calcium chloride optimizes coagulation, especially in commercial cheese production where consistency and texture are critical.

Calcium Chloride vs No Additive for Milk Setting Infographic

cookingyes.com

cookingyes.com