Cold-start toasting requires placing bread in an oven before heating, allowing gradual warming that can result in uneven browning and longer toasting times. Using a preheated oven ensures consistent temperature from the start, producing evenly toasted slices with a crisp texture and shorter cooking duration. For batch toasting, a preheated oven offers efficiency and uniform results, making it the preferred method.

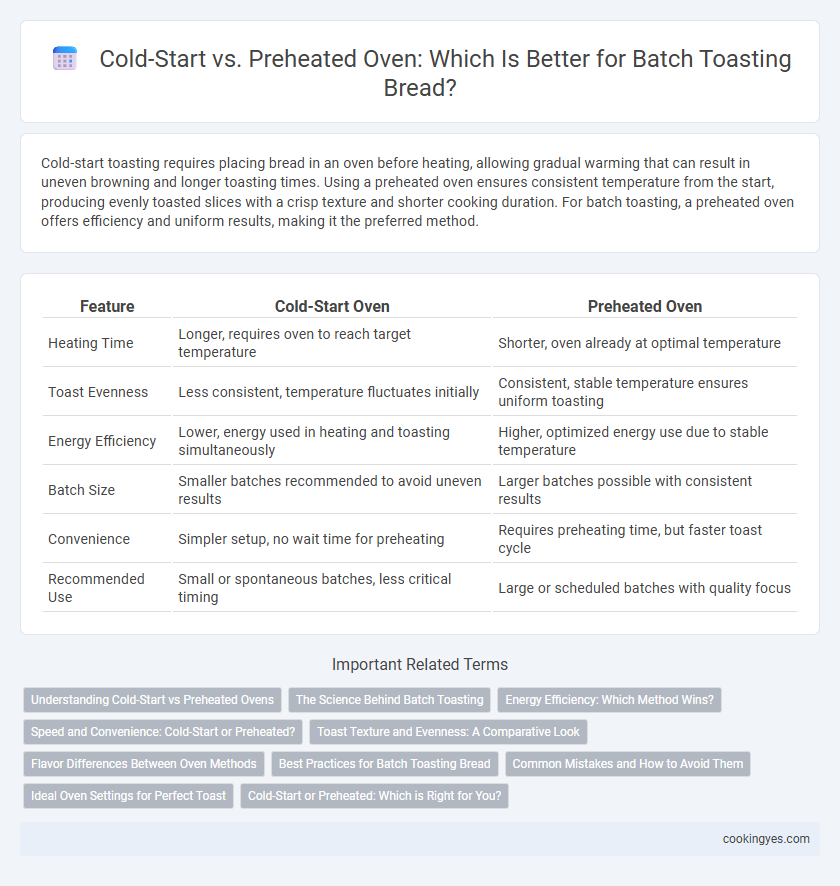

Table of Comparison

| Feature | Cold-Start Oven | Preheated Oven |

|---|---|---|

| Heating Time | Longer, requires oven to reach target temperature | Shorter, oven already at optimal temperature |

| Toast Evenness | Less consistent, temperature fluctuates initially | Consistent, stable temperature ensures uniform toasting |

| Energy Efficiency | Lower, energy used in heating and toasting simultaneously | Higher, optimized energy use due to stable temperature |

| Batch Size | Smaller batches recommended to avoid uneven results | Larger batches possible with consistent results |

| Convenience | Simpler setup, no wait time for preheating | Requires preheating time, but faster toast cycle |

| Recommended Use | Small or spontaneous batches, less critical timing | Large or scheduled batches with quality focus |

Understanding Cold-Start vs Preheated Ovens

Cold-start ovens begin baking at room temperature, gradually heating the bread which allows for even internal warming but may result in longer toasting times and a less crispy crust. Preheated ovens provide immediate high heat, promoting a rapid Maillard reaction that creates a crunchier, well-browned exterior while reducing overall toasting time. Understanding these differences helps optimize toast texture and flavor based on desired outcomes in batch toasting processes.

The Science Behind Batch Toasting

Batch toasting in a cold-start oven allows gradual heat absorption, resulting in more evenly browned bread due to consistent Maillard reaction progression. Preheated ovens deliver immediate high heat that intensifies surface caramelization but may cause uneven interior toasting and increased risk of burning. Understanding heat transfer dynamics and moisture evaporation rates is critical for optimizing crispness and texture in batch toasting processes.

Energy Efficiency: Which Method Wins?

Cold-start toasting uses less overall energy by eliminating the need to preheat the oven, making it more efficient for small batches. Preheated ovens consume additional electricity during the warm-up phase, increasing energy usage despite potentially faster toasting times. Energy efficiency studies show cold-start methods reduce power consumption by up to 20%, favoring sustainability in batch toasting.

Speed and Convenience: Cold-Start or Preheated?

Cold-start toasting saves time by eliminating preheating, making it faster for single or small batches, but may result in uneven browning. Preheated ovens ensure consistent heat distribution for uniform toast, ideal for larger batches despite a longer overall wait. Choosing between cold-start and preheated depends on balancing speed with desired toast quality and batch size.

Toast Texture and Evenness: A Comparative Look

Using a preheated oven for batch toasting ensures consistent heat distribution, resulting in evenly browned toast with a crisp texture. Cold-start toasting often leads to uneven cooking, as the gradual temperature rise can cause sections to remain underdone or overly dry. For optimal toast texture and evenness, preheating the oven is recommended to achieve uniform crispness and color.

Flavor Differences Between Oven Methods

Cold-start toasting allows bread to warm gradually, promoting Maillard reactions that enhance nutty and caramelized flavor notes, resulting in a more complex taste profile. Preheated ovens deliver immediate high heat, producing a quicker crust formation with a crisper texture and more intense surface browning but less depth in flavor development. The slower temperature rise in cold-start methods encourages even moisture evaporation, preserving subtle aromatic compounds often lost in rapid preheating.

Best Practices for Batch Toasting Bread

Using a preheated oven ensures consistent heat distribution, resulting in evenly toasted bread slices with a crisp texture and reduced toasting time. Cold-start batch toasting may cause uneven cooking and longer bake times, affecting quality and efficiency. For optimal results, place bread on a wire rack in a fully preheated oven at 350degF (175degC), flipping halfway to maintain uniform browning.

Common Mistakes and How to Avoid Them

Cold-starting a toaster oven often leads to uneven browning and extended cooking times due to the appliance gradually reaching the desired temperature. Preheating the oven ensures consistent heat distribution, preventing under-toasted spots and reducing the risk of burning. Avoid cycling between cold-starts by allowing the oven to reach the target temperature before placing bread inside, which optimizes toasting efficiency and texture.

Ideal Oven Settings for Perfect Toast

Ideal oven settings for perfect toast vary depending on cold-start versus preheated methods; a preheated oven set at 350degF (175degC) ensures even heat distribution, promoting uniform browning and crispness. In contrast, cold-starting the oven requires slightly longer toasting time, typically around 15-20 minutes at 325degF (163degC), allowing gradual warming and reducing the risk of burning. Monitoring internal oven temperature stability and using convection mode can enhance consistency and achieve the desired golden-brown texture in batch toasting.

Cold-Start or Preheated: Which is Right for You?

Cold-start toasting uses an oven heated from room temperature, allowing bread to warm gradually and develop a more even texture without burning. Preheated oven toasting delivers faster results with consistent browning, ideal for busy kitchens needing efficiency and repeatability. Choose cold-start for enhanced flavor depth, while preheated suits quick, reliable batch toasting demands.

Cold-start vs preheated oven for batch toasting Infographic

cookingyes.com

cookingyes.com