Wet cured ham is preserved by soaking or injecting the meat with a brine solution, which helps retain moisture and results in a tender, juicy texture. Dry cured ham involves rubbing the meat with salt and spices, then aging it over time, producing a firmer texture and more concentrated flavors. Both methods effectively preserve the ham, but wet curing offers a shorter curing period and milder taste, while dry curing provides a longer shelf life and intensified flavor profile.

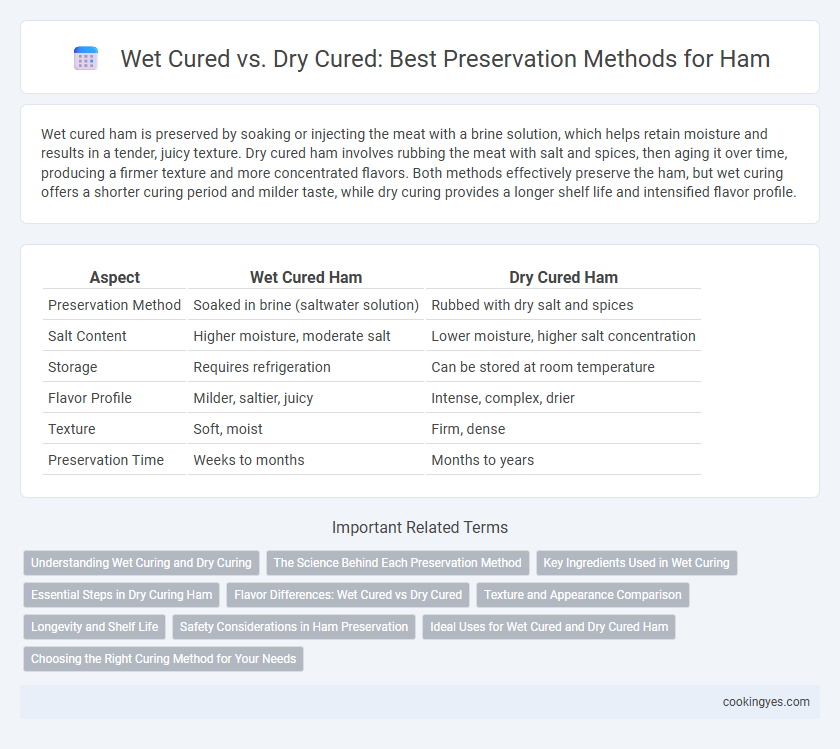

Table of Comparison

| Aspect | Wet Cured Ham | Dry Cured Ham |

|---|---|---|

| Preservation Method | Soaked in brine (saltwater solution) | Rubbed with dry salt and spices |

| Salt Content | Higher moisture, moderate salt | Lower moisture, higher salt concentration |

| Storage | Requires refrigeration | Can be stored at room temperature |

| Flavor Profile | Milder, saltier, juicy | Intense, complex, drier |

| Texture | Soft, moist | Firm, dense |

| Preservation Time | Weeks to months | Months to years |

Understanding Wet Curing and Dry Curing

Wet curing involves immersing ham in a brine solution containing water, salt, sugar, and curing agents, ensuring moisture retention and a tender texture. Dry curing requires rubbing the ham with a mixture of salt, nitrates, and spices, leading to moisture extraction and intensified flavors through slow dehydration. Both preservation methods inhibit microbial growth, with wet curing producing a moist, milder ham and dry curing yielding a denser, more concentrated taste.

The Science Behind Each Preservation Method

Wet cured ham preserves meat by soaking it in a brine solution containing salt, sugar, and nitrates, which inhibits bacterial growth through osmotic pressure and chemical preservation. Dry cured ham relies on the application of salt and natural enzymes that draw moisture out, creating an environment unsuitable for harmful bacteria while allowing enzymatic reactions to develop complex flavors. The distinct preservation mechanisms impact texture, shelf life, and taste profiles, with wet curing offering quicker preservation and dry curing providing deeper flavor maturation.

Key Ingredients Used in Wet Curing

Wet cured ham preservation relies on key ingredients such as water, salt, nitrites, and sugars to enhance flavor and inhibit bacterial growth. The brining solution often includes sodium nitrate or sodium nitrite to prevent botulism and maintain the ham's pink color. Sugar, typically sucrose or dextrose, balances the saltiness and supports fermentation processes during curing.

Essential Steps in Dry Curing Ham

Dry curing ham involves rubbing the meat thoroughly with a mixture of salt, sugar, and spices to draw out moisture and inhibit bacterial growth. The ham is then tightly wrapped and stored in a controlled environment, typically at low temperatures and high humidity, to promote even curing and develop complex flavors. This method relies on extended curing times, often several months, to achieve optimal texture and preservation compared to the faster wet curing process.

Flavor Differences: Wet Cured vs Dry Cured

Wet cured ham undergoes a brining process that imparts a moist, salty, and slightly tangy flavor, enhancing tenderness and juiciness. Dry cured ham is coated with salt and aged over time, resulting in a more concentrated, complex, and savory taste with subtle nutty and sweet undertones. The preservation methods significantly influence the texture and flavor depth, with wet curing emphasizing moisture retention and dry curing promoting rich, intense flavor development.

Texture and Appearance Comparison

Wet cured ham typically has a moister, softer texture due to the brine injection process, which helps retain water and results in a paler, pinkish appearance. Dry cured ham undergoes a longer aging period with salt and air exposure, creating a firmer texture and a darker, more intense color with a visible rind or mold surface. The preservation method directly influences the ham's mouthfeel and visual appeal, with wet curing offering tenderness and dry curing providing complexity and depth in both texture and appearance.

Longevity and Shelf Life

Wet cured ham is preserved by soaking in brine or injecting saline solution, which extends its shelf life to several weeks when refrigerated but generally requires cold storage and has a shorter longevity compared to dry cured ham. Dry cured ham undergoes a salting and air-drying process that significantly dehydrates the meat, resulting in a shelf life that can last from several months to years without refrigeration due to the reduced moisture content inhibiting microbial growth. The choice between wet cured and dry cured ham for preservation depends on desired shelf life and storage conditions, with dry curing offering superior longevity and stability at room temperature.

Safety Considerations in Ham Preservation

Wet cured ham, preserved through brining or injection of saltwater solutions, ensures microbial safety by inhibiting bacterial growth via high moisture content combined with salt concentration. Dry cured ham relies on salt and controlled drying conditions to reduce water activity, creating an environment hostile to pathogens but requiring precise humidity and temperature control to prevent spoilage. Both methods demand strict hygiene and storage protocols to minimize risks of contamination and ensure safe consumption.

Ideal Uses for Wet Cured and Dry Cured Ham

Wet cured ham, preserved through brining or injection with a saltwater solution, is ideal for moist, tender dishes such as baked ham, sandwiches, and soups due to its higher moisture content. Dry cured ham, cured with a salt rub and aged over time, is best suited for slicing thinly and serving as charcuterie, in salads, or as a flavorful addition to antipasto platters, offering a concentrated, intense flavor. The preservation method directly influences the texture and taste, guiding culinary applications based on moisture retention and flavor depth.

Choosing the Right Curing Method for Your Needs

Wet cured ham involves soaking the meat in a brine solution, which enhances moisture retention and results in a juicier texture, making it ideal for recipes requiring tenderness. Dry cured ham is preserved by rubbing salt and spices directly onto the meat, promoting a more intense flavor and longer shelf life, suitable for charcuterie and aged delicacies. Selecting between wet and dry curing depends on desired taste, texture, and storage preferences, with wet curing favoring succulence and dry curing emphasizing robust flavor and preservation.

Wet Cured vs Dry Cured for Preservation Infographic

cookingyes.com

cookingyes.com